STA311-125-140-006/1 is a rod seal that works as single acting and can be used in rod applications. The material used on this rod seal is made of PTFE+BRONZE/NBR 70 shore. The maximum allowed pressure is 400 BAR.

The dimensions has an inner diameter of 125 mm, an outer diameter of 140.5 mm and a height of 6.3 mm.

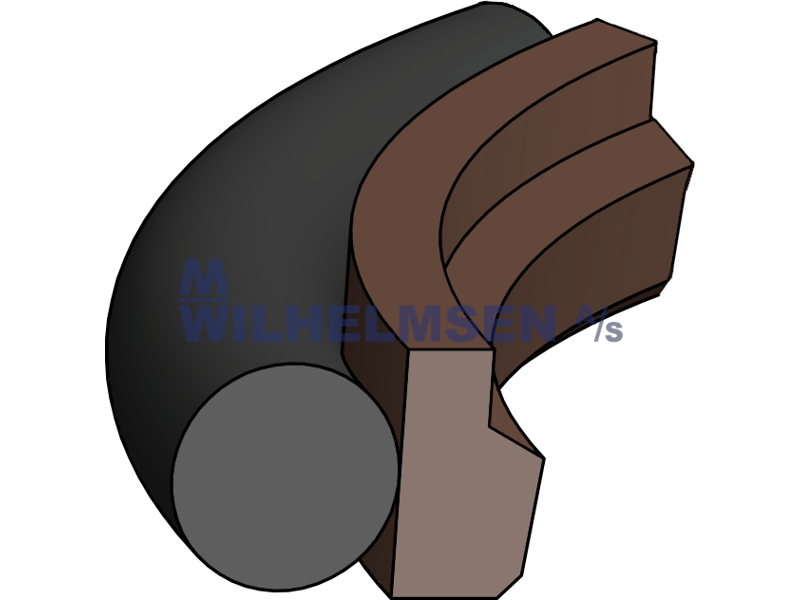

About the sealing profile STA311

STA311 rotary rod seals are composed of a special compound of bronze-filled PTFE which is then combined with an o-ring that is used as an energizing ring. They are designed to provide imperviousness under high pressure in rotary applications. They are suitable for high sliding speeds due to the low friction force which is among one of the essential properties of PTFE material. Moreover, they can be used for different type of oils except mineral oils by changing o-ring material.

About the material PTFE+BRONZE/NBR

Improves thermal resistance, high pressure stability and extrusion resistance. It is the most preferred filler for hydraulic applications. Nitrile is a widely used nitrile butadiene and acrylo nitrile polymer. The NBR formulas typically contains between 30% and 50% acrylonitrile (ACN). The NBR which has a working temperature between -30°C and +105°C (peak temp. at +130°C) show extremely high resistance under different working conditions such as mineral oils (H, H-L and H-LP type lubricating oils) and grease and mineral based fire resistance oils (HFB and HFC group oils), vegetable and organic oils, and aliphatic hydrocarbons (propane, butane, petrol). NBR is not recommended for aromatic hydrocarbons (benzene, trichloroethylene, HFD type fire resistance oils), glycol and ether contained break hydraulics.