STA155-110-130-032 is a compact seal that works as single acting and can be used in rod applications. The material used on this compact seal is made of NBR/TPE/POM 80 shore. The maximum allowed pressure is 700 BAR.

The dimensions has an inner diameter of 110 mm, an outer diameter of 130 mm and a height of 32.5 mm.

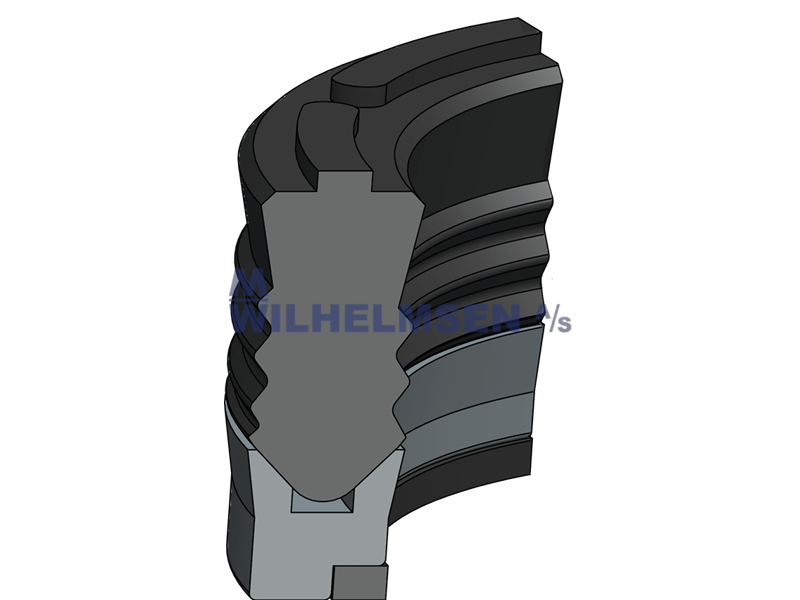

About the sealing profile STA155

STA155 Heavy duty rod seals are designed as an alternative for packings. Its special profile consist of a NBR ring, a POM back-up ring and a TPE ring. STA155 Rod seals offer better results especially in systems in which hydraulic shock pressures occur.

About the material NBR/TPE/POM

Nitrile is a widely used nitrile butadiene and acrylo nitrile polymer. The NBR formulas typically contains between 30% and 50% acrylonitrile (ACN). The NBR which has a working temperature between -30°C and +105°C (peak temp. at +130°C) show extremely high resistance under different working conditions such as mineral oils (H, H-L and H-LP type lubricating oils) and grease and mineral based fire resistance oils (HFB and HFC group oils), vegetable and organic oils, and aliphatic hydrocarbons (propane, butane, petrol). NBR is not recommended for aromatic hydrocarbons (benzene, trichloroethylene, HFD type fire resistance oils), glycol and ether contained break hydraulics. TPE materials are widely used in hydraulic-pneumatic applications with a variety of combinations due to their high resistance to mineral oils and high tensile strength. Working temperature is between -40°C and +120°C. Polyacetal (POM) (Polyoxymethylene) materials are used as back-up rings or guidening element materials in hydraulic and pneumatic systems. There are two types of POM, filled with or without fibreglass, depending on their use. Despite working temperatures ranging from -40°C to +140°C, real dimensions can not remain stable in excess of 100°C. It can be used safely with mineral oils and HFA, HFB type oils. Types with added fibreglass provide longer lasting contact pressure resistance.